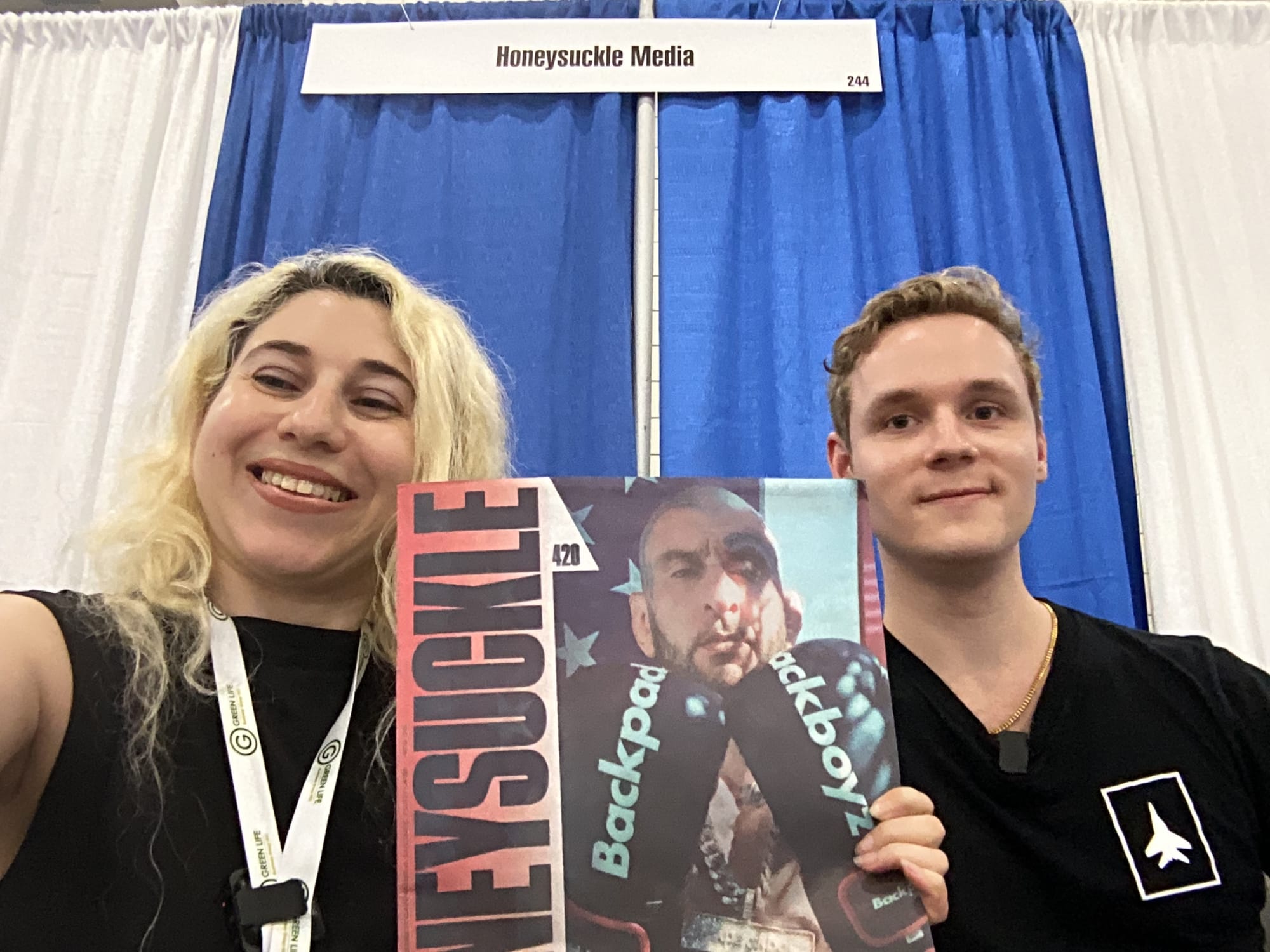

When it comes to innovation in cannabis concentrates, Vape-Jet is quietly setting a new industry standard—one automated cartridge at a time. At the Cannabis Means Business Expo in New York City, one of the largest and oldest cannabis trade shows in North America, we caught up with Vape-Jet Sales Lead Sawyer Sheppard. He shared how the Oregon-based company is changing the way producers scale, preserve flavor, and stay true to the plant.

What Is Vape-Jet? Vape Filling Tech With Care

“Vape-Jet is an automated cartridge filling machine,” Sheppard explained. “That’s our primary product, but we’re pretty much all things concentrate dispensing. What we like to do is innovate and engineer products that are developed specifically for the cannabis industry.”

The company focuses on developing tech with care for the oil, and its origin is as scrappy as it is thoughtful. About five years ago, Vape-Jet’s founder was trying to scale a lab and noticed how manual filling was damaging the process, particularly where his partners hands were concerned.

“Hand filling is inaccurate, hot, [painful to your] hands,” Sheppard said. “It’s not a fun thing to do. None of the machines out there took the care on how to treat the plant, nor [provided] the care, quality, and efficiency that was needed in big-scale filling. He made his own machine. Someone asked to buy it, and he said no, but people just kept asking. So he turned it into a company.”

Between Science And Art: How Vape-Jet Preserves Terpenes

Since then, Vape-Jet has evolved into a modular, AI-enhanced system that can handle everything from carts to capsules to infused pre-rolls. But its signature strength? Preserving terpenes.

“There are a lot of variables when it comes to vape filling,” Sheppard emphasized. “It seems pretty simple… but the tech is still really new, both on the cartridge and hardware sides. The vein of it is that cannabis oil hates heat and oxygen. It ruins the product. But you do need to use heat to make it through a vape cart because it’s thick like molasses. To do that with care, we use a pressurized vessel with nitrogen that secures the terpenes to make sure that the flavor profile is exhibited. You can have amazing genetics and traction, but then if you burn your oil right before you put it into a finished product, what’s the point of all those steps before? That’s what [Vape-Jet does]. We ensure that the quality is preserved, and that the cultivators’ genetics are expressed, even though vaping is a much different form than just straight-up smoking cannabis.”

This approach sits at the crossroads of science and art. “It’s an intersection,” Sheppard agreed. “Engineering and science have to come into play. We’re funding more research in every sector so rapidly now with legalization across the U.S. Cannabis doesn’t just sell itself anymore… You have to do the research, test, see what breaks, what tastes good and what doesn’t, and find the data points in there. For oil, it’s the viscosity and density. If you have a machine that fills just so much, but isn’t taking into effect the changes in density because of heat applied, then you’re going to end up with underfilled carts. Retailers and consumers are never going to buy your product again because they felt like they were shorted. So you need to know how much you’re doing in each weight to keep your brand effective.”

Rise Of Automation And AI: Vape-Jet Looks To The Future

Vape-Jet’s AI-driven machine vision system operates as “3D printing for concentrates.” According to Sheppard, this development allows the machine to adapt on the fly, recognizing different tray formats (carts, pods, disposables, diamond containers), filling viscosities, and concentrate types without requiring users to create custom trays or swap equipment. And despite the rise of automation, he firmly believes that the tech creates opportunity.

“Automation doesn’t replace jobs; it upgrades them,” he said. “I’ve seen it firsthand at labs. People are freed up [instead of] doing menial tasks. Machines allow us to do more creative work, to express ourselves and have more time for art and nature. As soon as people get their machine, their quality of life goes up. They get promoted at their job, move into manager and operator roles, and there are more revenue streams for the entire business. It’s an upscaling and a good investment [for the future of your employees].”

Education is a key part of that philosophy. Vape-Jet offers robust resources even for those who aren’t ready to invest in machinery. Whether you're a home grower with a medical need or a startup scaling production, the company’s goal is to support smart growth.

“We don’t just want to sell you a machine that’s going to grow your business,” Sheppard noted. “We want to partner, to make sure you have the education about vape filling, the concentrates you’re buying, and better the whole product. [Our vision system] can help with that in a lot of ways. We distill information, collect data, and create [customer-specific] resources.”

Vape-Jet's Commitment To Craft And Community

Currently, about 50 percent of Vape-Jet’s customers are craft cultivators and processors. “We do have large producers, because the machine caters to different audiences, but I think the craft cultivators and extractors understand it a little more,” Sheppard admitted. “They have that attention to detail. They’re working with rosin and live resin, and creating a concentrate that tastes amazing to vape or dab. They care. They want to slow down the conversation and learn every day. And the people who care are the most fun to work with.”

He added, “That’s what I love, that’s one of the coolest parts about this industry: The innovation never stops.”

Sheppard noted that craft cultivators in the Northeast have been particularly impressive, with markets like Maine and Vermont producing tech that in his opinion “rivals or even surpasses California in some cases.”

Different concentrates require different calibrations. Rosin, for example, gets filled at a lower temperature to protect its terpene profile. Vape-Jet’s equipment lets processors fine-tune the process, preserving flavor and consistency across batches.

What's Next For Vape-Jet? East Coast Expansion

The company is also expanding, soon to open a second manufacturing location in Pittsburgh to better serve East Coast clients. “We’re all made in the U.S., and we want to be closer to this incredible community,” Sheppard said. “There’s a deep history [of creativity]. In the Northeast, they’re finding genetics that are a little more rare or old-school, and they’re expressing and growing them in modern environments with more control and more data. Now they’re creating some of the best, most impressive products I’ve ever tasted.”

Even as the industry matures, Vape-Jet remains rooted in its mission to support people at every level of the supply chain. That includes numerous activations that occurred around the July 10th holiday (710, also known as “Oil Day”), blog resources, and collaborations with some of their most exciting brands, such as the women-owned brand TribeTokes.

“The passion in New York is contagious,” Sheppard enthused.

And if you’re wondering how serious the team is about honoring the culture? Sheppard got married on Oil Day itself.

“We didn’t plan it that way, but it fits,” he laughed.

From automated precision to community-driven growth, Vape-Jet is proof that the future of vaping lies in respecting the past—while engineering what’s next.

For more about Vape-Jet, visit vape-jet.com or follow @vape_jet on Instagram.

To learn more about the Cannabis Means Business Expo and see highlights from the 2025 show, visit cannabismeansbusiness.com.

Find Out More On Social

--

Featured image: Sawyer Sheppard, Sales Lead at Vape-Jet (C) Vape-Jet