Cesaria, Israel — The headquarters of Hefestus doesn’t look like the birthplace of a manufacturing revolution. It’s quiet. No theatrics. Just machines, engineers, and the hum of precision. But inside these walls, father–son duo Yehuda and Shahar Yamay have built something the industry didn’t know it needed — and now can’t operate without.

This isn’t a tech fairy tale. It’s a story about engineering obsession, stubborn problem-solving, and two minds that approach innovation from entirely different angles — and somehow make it work.

Yehuda Yamay: The Reluctant Pioneer

Ask Yehuda how he started and he shrugs, almost amused by the simplicity of it.

“I started in my garage,” he says, as if that explains the machines now installed from Indiana to Europe. “Medical, food, cosmetics… it never mattered. Cream, paste, sauce — it’s all mechanics.”

It’s this stripped-down engineering logic that pulled him into cannabis almost by accident. A friend refused to keep hand-packing pre-rolls “like the rest of the industry,” and Yehuda — who never saw a mechanical challenge he didn’t want to beat — built his first pre-roll machine in 2014.

That single machine quietly rewired an industry still stuck in artisanal mode. By the time competitors realized the shift, Hefestus was already three steps ahead.

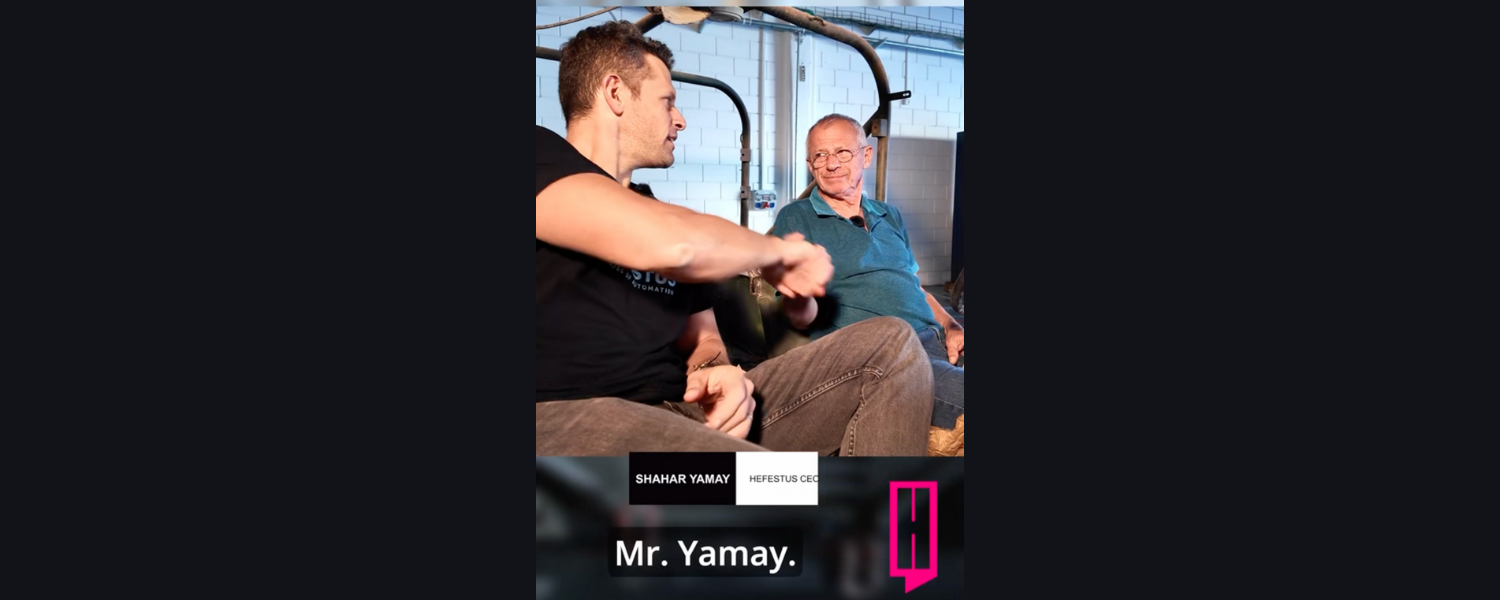

Shahar Yamay: The Accidental Successor Who Became the Engine

Shahar, now CEO, has a different story. He grew up with machines but escaped into tech, avoiding the family business as long as he could.

“My father told me, I have five kids and you’re the only one who doesn’t know how to replace a lamp,” Shahar jokes — then immediately stops his father from telling the story the “embarrassing” way.

But once he stepped into Hefestus, the company didn’t just grow — it accelerated.

“From the moment he came in,” Yehuda admits, almost grudgingly, “we’ve grown more than 100% every year.”

Shahar brought structure, software, interface thinking, and global communication — transforming his father’s raw engineering into a scalable ecosystem.

Machines Built to Solve Problems, Not Impress Investors

Hefestus doesn’t build showpieces. Nothing here was designed to “look innovative.” Everything solves a problem that existed yesterday.

Take the grinders.

Shahar gestures toward the PSCA:

“It grinds up to 75 kg an hour. And that’s the modest number.”

Its bigger sibling, the PSC-10, doubles that output. Both keep temperatures remarkably low — not as a buzzword, but because it preserves product integrity.

Even their small machines feel like industrial creatures built for war, not display.

Then there’s the cone-cutter — a solution born from the chaos of COVID.

As people stopped sharing joints, demand for tiny single-use cones exploded, leaving producers stockpiling dozens of lengths.

“It was insane,” Yehuda recalls. “You had to keep huge inventory just in cone sizes.”

His answer was beautifully blunt:

One universal cone paired with a precision cutter that trims it to any length on demand.

It wasn’t flashy. It was brilliant. And it became a new industry standard almost overnight.

Remote Engineering Before It Was Trendy

While other companies brag about IoT dashboards, Hefestus simply does it.

Every machine connects to the network. Engineers in Cesaria routinely troubleshoot devices in Indiana in real time — watching the machine, diagnosing, and fixing issues without stepping onto a plane.

“Ninety-five percent of problems are solved remotely,” Yehuda says. And he means it literally.

This isn’t “digital transformation.” It’s engineering efficiency — the kind born from having no patience for avoidable downtime.

The Dynamic That Makes the Machine Work

What makes Hefestus stand out isn’t simply the engineering. It’s the creative tension between two very different minds. Yehuda brings instinct and mechanical ingenuity; Shahar brings clarity, system thinking, and a global orientation. The result is a company that never set out to lead an industry — but ended up doing it anyway.

In a sector full of loud promises and overbuilt prototypes, Hefestus took a quieter path: they solved real problems, built machines that don’t break, and let the results speak for themselves. And in doing so, a modest garage project in Israel became a critical backbone of modern cannabis production — not because it aimed for the spotlight, but because it earned it.

If you want, I can also create a headline variation, subheading, pull quotes, or a shorter 600-word version for publication.

Cesaria, Israel — The headquarters of Hefestus doesn’t look like the birthplace of a manufacturing revolution. It’s quiet. No theatrics. Just machines, engineers, and the hum of precision. But inside these walls, father–son duo Yehuda and Shahar Yamay have built something the industry didn’t know it needed — and now can’t operate without.

This isn’t a tech fairy tale. It’s a story about engineering obsession, stubborn problem-solving, and two minds that approach innovation from entirely different angles — and somehow make it work.

Yehuda Yamay: The Reluctant Pioneer

Ask Yehuda how he started and he shrugs, almost amused by the simplicity of it.

“I started in my garage,” he says, as if that explains the machines now installed from Indiana to Europe. “Medical, food, cosmetics… it never mattered. Cream, paste, sauce — it’s all mechanics.”

It’s this stripped-down engineering logic that pulled him into cannabis almost by accident. A friend refused to keep hand-packing pre-rolls “like the rest of the industry,” and Yehuda — who never saw a mechanical challenge he didn’t want to beat — built his first pre-roll machine in 2014.

That single machine quietly rewired an industry still stuck in artisanal mode. By the time competitors realized the shift, Hefestus was already three steps ahead.

Shahar Yamay: The Accidental Successor Who Became the Engine

Shahar, now CEO, has a different story. He grew up with machines but escaped into tech, avoiding the family business as long as he could.

“My father told me, I have five kids and you’re the only one who doesn’t know how to replace a lamp,” Shahar jokes — then immediately stops his father from telling the story the “embarrassing” way.

But once he stepped into Hefestus, the company didn’t just grow — it accelerated.

“From the moment he came in,” Yehuda admits, almost grudgingly, “we’ve grown more than 100% every year.”

Shahar brought structure, software, interface thinking, and global communication — transforming his father’s raw engineering into a scalable ecosystem.

Machines Built to Solve Problems, Not Impress Investors

Hefestus doesn’t build showpieces. Nothing here was designed to “look innovative.” Everything solves a problem that existed yesterday.

Take the grinders.

Shahar gestures toward the PSCA:

“It grinds up to 75 kg an hour. And that’s the modest number.”

Its bigger sibling, the PSC-10, doubles that output. Both keep temperatures remarkably low — not as a buzzword, but because it preserves product integrity.

Even their small machines feel like industrial creatures built for war, not display.

Then there’s the cone-cutter — a solution born from the chaos of COVID.

As people stopped sharing joints, demand for tiny single-use cones exploded, leaving producers stockpiling dozens of lengths.

“It was insane,” Yehuda recalls. “You had to keep huge inventory just in cone sizes.”

His answer was beautifully blunt:

One universal cone + a precision “scissor” that cuts it to any length on demand.

It wasn’t flashy. It was brilliant. And it became a new industry standard almost overnight.

Remote Engineering Before It Was Trendy

While other companies brag about IoT dashboards, Hefestus simply does it.

Every machine connects to the network. Engineers in Cesaria routinely troubleshoot devices in Indiana in real time — watching the machine, diagnosing, and fixing issues without stepping on a plane.

“Ninety-five percent of problems are solved remotely,” Yehuda says. And he means it literally.

This isn’t “digital transformation.” It’s engineering efficiency — the kind born from having no patience for avoidable downtime.

The Dynamic That Makes the Machine Work

The magic of Hefestus isn’t just the machines. It’s the friction between Yehuda’s old-school rugged engineering and Shahar’s structured, modern execution.

Yehuda builds.

Shahar scales.

And together, they’ve created one of the most quietly influential companies in cannabis manufacturing — without ever trying to look like one.

Hefestus doesn’t chase buzzwords.

They chase solutions.

And somehow, that turned a garage project into a global backbone for an industry racing to grow up.

For more, visit hefestus-tech.com. And Catch them at booth #C21613